English

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-11-14 Origin: Site

Maximizing warehouse space is key to operational success. But how do you choose between racking and mezzanine systems? Both are designed to optimize space, yet they serve different purposes.

In this article, we will dive into the differences between racking and mezzanine systems. You'll learn which system best suits your business needs based on functionality, cost, and efficiency.

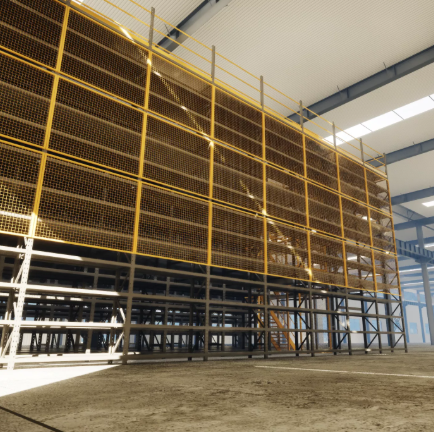

A mezzanine system is a semi-permanent elevated platform that creates an additional level within an existing warehouse or industrial space. It is supported by structural steel columns, which bear the load of the added level, and typically utilizes metal decking or steel plates for the floor surface. Mezzanines are highly customizable, which allows them to be used for a variety of purposes including storage, office space, production areas, assembly zones, or even retail displays.

One of the standout features of mezzanine systems is their ability to significantly increase usable space without the need for a full-scale construction project or building expansion. This makes mezzanine floors particularly useful for businesses that need more space but are constrained by property limitations or budget restrictions. The modular nature of mezzanines also means that they can be tailored to the specific dimensions of a facility, offering maximum flexibility in terms of both layout and function.

A racking system refers to a shelving structure designed specifically for storing palletized goods in an organized and accessible manner. Racking systems are built to optimize vertical space by creating multiple levels of storage, ensuring efficient inventory organization. These systems are modular, meaning they can be easily reconfigured as business needs evolve. There are various types of racking systems, including selective pallet racks, drive-in racks, push-back racks, and others, each suited to different operational requirements.

Racking systems are especially beneficial in environments where managing a large volume of goods is essential. They allow warehouses to maximize storage density, creating narrow aisles that provide better organization and easier access to inventory. These systems focus on efficient storage and retrieval of goods, making them an ideal solution for companies that primarily handle palletized inventory.

Mezzanine: Mezzanine systems are designed to make the most of unused vertical space in a warehouse or facility. They essentially double or even triple the usable floor area within the same building footprint. This makes them ideal for businesses that need more room but cannot afford the costs associated with relocating or expanding their physical building. With a mezzanine, companies can take advantage of vertical space to create additional storage areas or office spaces without the need for construction.

Racking: Racking systems focus on maximizing storage density within the available horizontal and vertical space. By creating multiple levels of shelving and narrow aisles between racks, they optimize the storage of palletized goods, ensuring high-density storage while maintaining accessibility. These systems are best suited for businesses with high volumes of inventory that need efficient organization and quick access to stored goods.

Mezzanine: One of the key advantages of mezzanine systems is their versatility. They can serve a variety of functions beyond just storage. In addition to providing additional space for inventory, mezzanines can be used for office areas, packing and shipping zones, assembly lines, or even as break rooms for employees. This flexibility makes mezzanines particularly useful for businesses that require multi-functional spaces within a single building, helping to maximize the utility of the available floor area.

Racking: Racking systems, in contrast, are primarily focused on storage. They are designed to store palletized goods efficiently, and while they can be adapted to different types of inventory, their primary purpose is to organize and optimize storage. Racking systems are particularly useful in environments where businesses deal with large quantities of standard-sized inventory, and the focus is on quick access and efficient storage of pallets.

Mezzanine: Mezzanine systems are typically built to support heavy loads, which makes them suitable for a variety of materials, including heavy machinery, industrial equipment, and bulk goods. The load-bearing capacity of a mezzanine depends on the materials used in its construction, such as steel or metal decking. These systems are designed to handle substantial weight, and it’s important to ensure proper structural assessments are made before installation to confirm that the mezzanine can handle the required load.

Racking: Racking systems are also built to support significant loads, but the capacity varies depending on the type of racking used. Selective pallet racks, for example, are designed to support lighter loads, while more specialized systems like drive-in racks or push-back racks can handle heavier goods. Racking systems are optimized for the storage of palletized inventory, and each type of racking is designed to support a specific weight range, depending on the configuration and material strength.

| Feature | Mezzanine System | Racking System |

|---|---|---|

| Space Utilization | Optimizes vertical space, creating additional floors | Maximizes horizontal and vertical space for palletized goods |

| Versatility | Multi-functional: storage, office, production, etc. | Primarily focused on storage and inventory organization |

| Load Capacity | High load-bearing capacity for heavy machinery | Varies by type, typically designed for palletized goods |

| Functionality | Customizable for various business needs | Optimizes storage for high volumes of palletized inventory |

| Construction Requirements | Requires structural assessments and customization | Easier to install and modular |

If your business requires more than just storage space, a mezzanine is the ideal solution. Mezzanines provide the flexibility to create a multi-functional space that can be used for a variety of purposes, such as office spaces, production areas, or storage. This makes them especially useful for businesses that need additional space for different activities within the same warehouse or facility. By utilizing the full height of the building, a mezzanine system can create multiple levels of usable space without the need for new construction.

A mezzanine system is perfect for facilities with high ceilings that have underutilized vertical space. Installing a mezzanine allows you to fully exploit this unused area and increase your operational capacity. Whether you need more room for storage, office spaces, or assembly areas, mezzanines provide a cost-effective solution to maximize the available vertical space and enhance productivity without requiring expensive building expansion or relocation.

Investing in a mezzanine floor can significantly increase the value of your facility. Unlike temporary solutions, mezzanines offer a permanent solution to space constraints, allowing businesses to expand their operations without the need for costly construction projects. The ability to customize the mezzanine to suit your facility’s specific needs also ensures that it will continue to serve your business as it grows, making it a valuable long-term investment for future-proofing your operations.

For businesses that primarily deal with palletized goods, a pallet racking system is the most efficient solution. These systems allow warehouses to store large quantities of inventory in a compact and organized manner. With narrow aisles and multiple levels of shelving, pallet racking systems maximize storage capacity while maintaining easy access to individual pallets. These systems are ideal for companies that handle high volumes of standardized inventory and require quick, easy access to products.

One of the main advantages of pallet racking systems is their flexibility and ease of installation. Unlike mezzanine floors, which require structural assessments and significant planning, racking systems can be set up quickly and with minimal disruption to ongoing operations. Additionally, racking systems are modular, meaning they can be reconfigured or expanded as storage needs evolve. This makes them ideal for businesses that anticipate changes in inventory or require flexible storage solutions.

Pallet racking systems generally have a lower initial investment compared to mezzanine systems. They are quicker to install and do not require extensive structural work, making them a more affordable solution for businesses with budget constraints. Racking systems are a cost-effective option for businesses that primarily need storage for palletized goods and do not require additional space for other operational functions.

Mezzanine: The cost of installing a mezzanine system can be higher due to the construction and customization required. Depending on the materials used, the complexity of the design, and the required structural assessments, the cost can range from $20 to $35 per square foot.

Racking: In contrast, pallet racking systems are more affordable, with costs ranging from $60 to $100 per pallet position. The installation process is simpler and faster, making it a more budget-friendly option for businesses with straightforward storage needs.

Mezzanine: Mezzanine systems offer higher long-term returns, especially in facilities where space is at a premium. By creating additional functional areas within the existing facility, mezzanines add significant value and operational capacity. This makes them a solid investment for businesses looking to expand without relocating or expanding their building.

Racking: Racking systems provide quicker ROI by improving storage efficiency and reducing operational costs. While they are primarily designed to optimize storage density for palletized goods, they are an excellent solution for businesses that require immediate, high-density storage solutions.

Mezzanine floors are best suited for businesses that need additional space for multiple functions. These include:

E-commerce fulfillment centers, which require space for storage, packing, and offices in the same facility.

Automotive parts storage, which may need assembly or inspection areas alongside storage.

Manufacturing plants that require both equipment storage and operational space for workers.

Pallet racking systems are ideal for businesses with large quantities of palletized inventory. Common use cases include:

Cold storage facilities, which require efficient storage solutions for perishable goods.

General warehouses dealing with large volumes of palletized SKUs.

Grocery distribution centers requiring quick access to inventory for fast turnover.

| Application | Mezzanine System | Racking System |

|---|---|---|

| E-commerce Fulfillment | Multi-functional space for storage, packing, offices | High-density storage for inventory and quick access |

| Automotive Parts Storage | Space for storage and assembly areas | Efficient storage for parts in pallets |

| Manufacturing Plants | Equipment storage and workspace for staff | Palletized inventory storage |

| Cold Storage Facilities | Not ideal for cold storage due to temperature concerns | Ideal for efficient cold storage organization |

| Grocery Distribution Centers | Storage and packing in multi-purpose areas | Quick retrieval and efficient palletized storage |

In conclusion, both mezzanine and racking systems offer unique advantages depending on your business’s needs. Mezzanine systems provide a flexible, long-term solution for businesses that need multi-functional space, while racking systems are ideal for maximizing storage density for palletized goods. Understanding your operational needs and facility layout is essential when choosing between these systems. Whether you need more space for diverse functions or require a high-density storage solution, both systems can enhance warehouse operations and efficiency.

Botro Group offers tailored solutions that cater to these needs, delivering efficient and space-optimizing products for various industries.

A: Racking systems are designed for high-density storage of palletized goods, maximizing vertical and horizontal space. Mezzanine systems add additional floors within existing facilities, providing versatile space for storage, office areas, and more.

A: Choose a mezzanine when you need multi-functional space or have high ceilings. It helps optimize vertical space for various activities, including storage and office functions, while racking systems are ideal for palletized goods storage.

A: Racking systems enhance efficiency by organizing inventory and creating narrow aisles, allowing for better storage density and easy access to goods, making them ideal for businesses managing large volumes of palletized goods.