English

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 45 Author: Site Editor Publish Time: 2025-10-17 Origin: Site

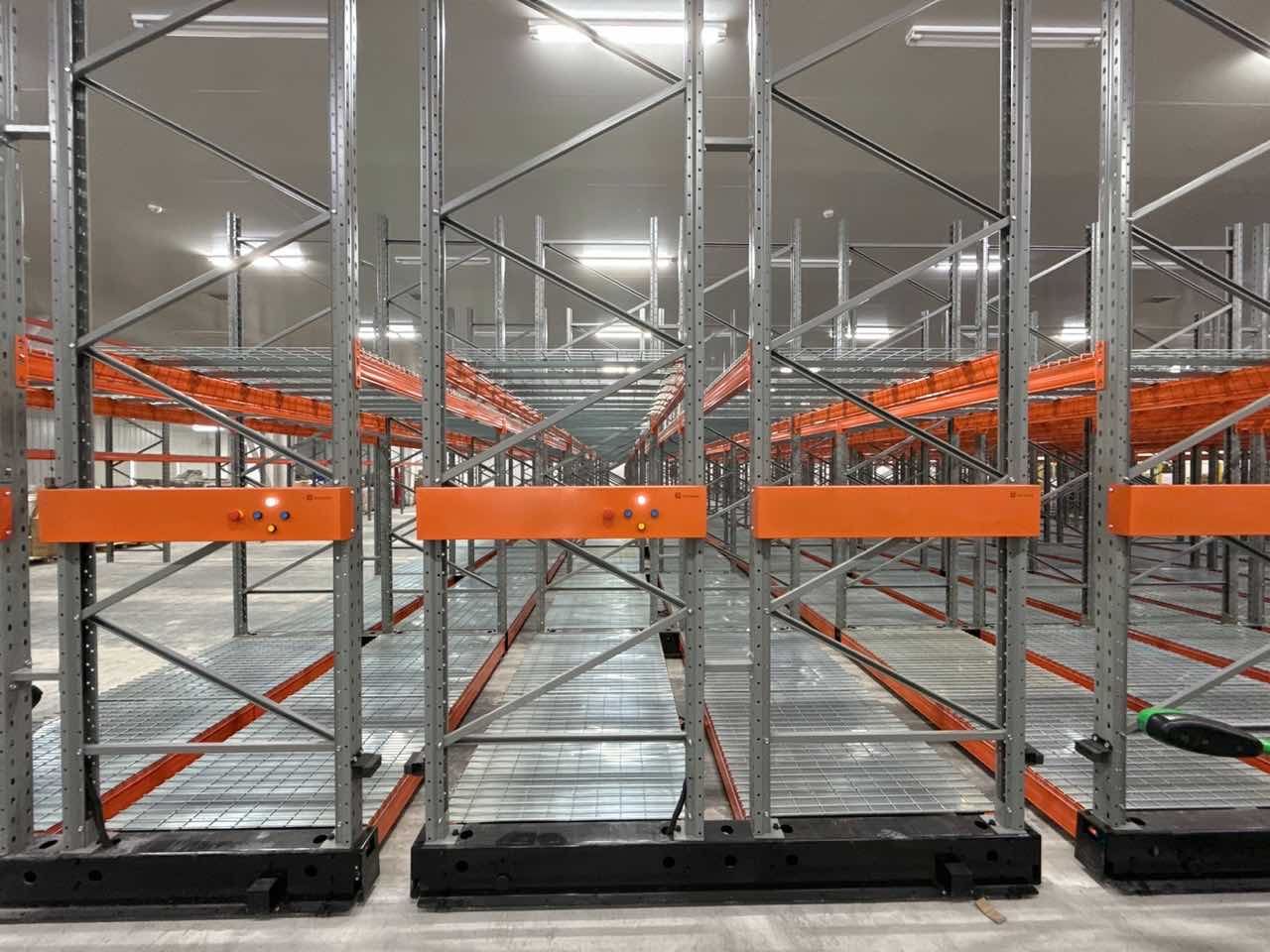

This is the mobile racking project recently completed by Botro, which located in Guangzhou, China. The project consists of six columns of mobile racking and two columns of static racking.

This warehouse has an area of approximately 600 square meters and a height of 4 meters. It has 6 columns of mobile racking and 2 columns of static racking. The aisle is 4 meters long. In order to meet the requirements of goods stacking, Botro mobile racking is designed with a single-layer load capacity of 3 tons, and each pallet can carry 1.5 tons. The customer requires forklift aisles on both sides, so the two sides of the mobile racking are connected and forklifts can run back and forth.

Based on the specific usage of this warehouse, it is necessary to leave forklift aisles on both sides. Eventually, a sliding rail wiring method was used, which is low-cost, occupies less space, and meets the needs of forklifts traveling on both sides.Botro Mobile racking has upgraded the stop switch. The old mobile racking only has an automatic stop switch inside the trolley. After the upgrade, the new mobile racking has added a second level stop switch on the column. When the first level stop switch loses its function, it will automatically activate the second level stop switch, making the rack safer.

In order to make mobile racking safer during use, the latest completed mobile racking project uses a second level stop switch. When the first level stop switch loses its function, the second level stop switch is automatically activated, and the moving racks will stop, ensuring the safety of the goods on the racks.

content is empty!

Introduction To Botro Mobile Roll Out Cantilever Racking System for China Project

Trackless Mobile Racking: A Game-Changer for Space Optimization in Warehouses

Exploring Mobile Pallet Racking: A Key To Streamlining Inventory Management

Trackless Vs. Track-Based Mobile Racking: Which System Is Right for Your Warehouse?