English

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-08-11 Origin: Site

You use a pallet racking system to keep palletized goods in your warehouse. This system has upright columns and horizontal beams to hold each pallet. It helps you keep things organized and makes it easy to get what you need. Good pallet racking lets you store more, work faster, and keep your warehouse safe. Companies like Botro Group have advanced pallet racking solutions for different warehouses. You can pick from many pallet racking types. Each type helps you handle pallets and make your warehouse work better.

Pallet racking systems keep pallets in order and safe. They help warehouses store more items in a smart way.

There are many types of racks for different jobs. Selective racks make it easy to get things. Drive-in racks hold a lot in a small space.

The racks use strong steel parts to stay steady. Safety features like column protectors help keep people and goods safe.

Checking and fixing racks often stops damage and accidents. This helps the warehouse stay safe and work well.

Picking the best rack depends on your warehouse size. It also depends on what you store and safety rules. This helps use space better and work faster.

When you go into a modern warehouse, you will see a pallet racking system. This system has strong metal frames and beams. These parts hold heavy pallets. All the parts work together to keep goods safe and neat. You should know the main parts before picking a pallet rack storage system for your warehouse.

Here is a table that lists the main parts and what they are made of:

Component | Description | Material(s) Commonly Used |

|---|---|---|

Uprights | Vertical supports that make the frame. They have footplates for balance. | Galvanized steel |

Diagonal Struts | Metal posts that join uprights diagonally. This gives extra strength. | Galvanized steel |

Frames | Uprights, diagonal struts, and footplates together give vertical support. | Galvanized steel |

Beams | Horizontal pieces that attach to frames and hold pallets. | Galvanized steel |

Crossbars | Metal pieces that go across beams. They stop pallets from falling. | Galvanized steel |

Bracing/Cross Bracing | Metal pieces that make the structure stronger. | Galvanized steel |

Shims | Metal pieces under racks to make them level on uneven floors. | Metal |

Locking Devices | Safety endplates welded to beams and uprights. | Metal |

Row Spacers | Steel parts that join uprights from different modules. | Steel |

Shelf Panels | Panels on beams. They can be grated, wooden, or metal. | Galvanized steel, wire mesh, wood |

Baseplates | Plates that anchor uprights to the floor. | Metal |

Wire Decking | Wire mesh decking supports pallets and stops falls. | Wire mesh |

Wood Stickers | Wood decking that helps support products. | Wood |

Column Protectors | Bolt-on parts that protect uprights from forklifts. | Metal |

Anchor Bolts | Bolts that anchor racks to the floor. | Metal |

You use these parts to build a strong pallet racking system. Uprights and beams make the main frame. Crossbars and bracing help keep it steady. Wire decking and shelf panels hold pallets and stop them from falling. Baseplates and anchor bolts keep the system in place on the floor. Column protectors help stop damage from forklifts.

A pallet racking system stores pallets in rows and levels. You put pallets on beams that connect to upright frames. You can move the beams up or down to fit different pallet sizes. This makes it easy to organize your warehouse and use space well.

Here is how the parts work together to hold heavy loads and keep your warehouse safe:

Upright frames give vertical support. They do not bend under heavy pallets. They are the backbone of the system.

Beams connect to uprights and spread the weight sideways. You can change shelf height to fit your needs.

Baseplates hold the uprights to the floor. This stops the racks from moving or falling.

Bracing and wire decking make the system stronger and help hold the load.

You should spread the load evenly and keep racks level. This lowers the chance of problems.

Check the racks often and fix them when needed. Use column protectors to stop forklift damage.

Modern pallet racking uses strong steel and extra bracing. Bolted or welded joints help racks hold more weight and stay stable.

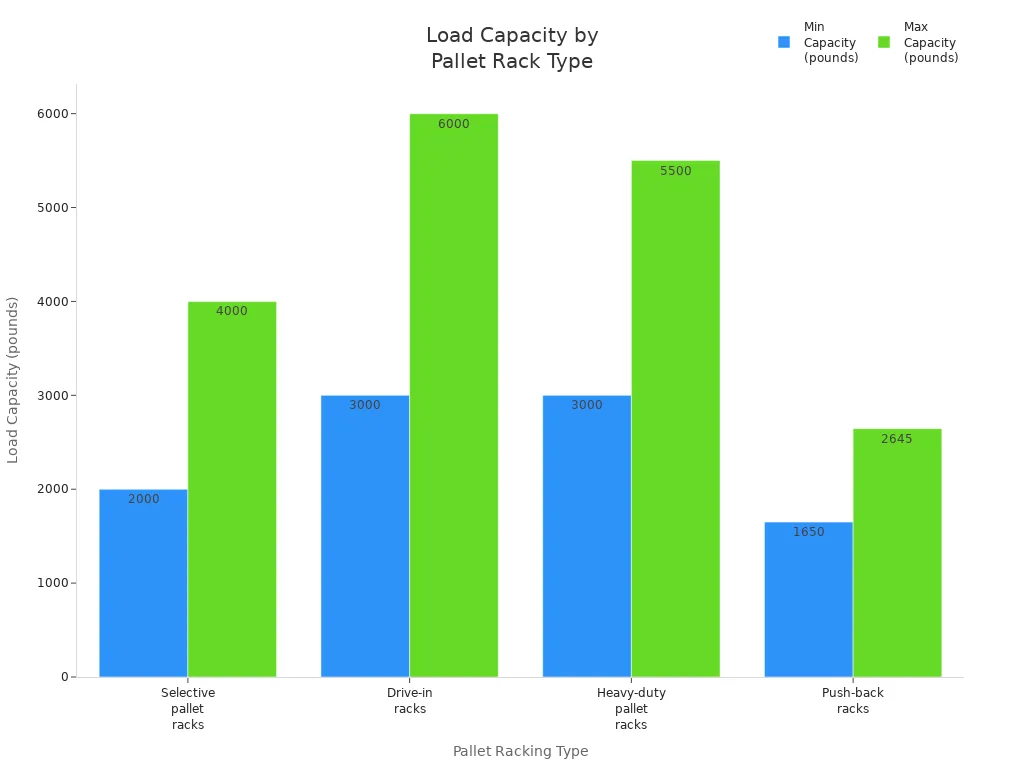

You need to know how much weight your pallet rack storage system can hold. Different pallet racking types hold different amounts. Here is a table that shows common load ranges:

Pallet Racking Type | Load Capacity Range (pounds) |

|---|---|

Selective pallet racks | 2,000 to 4,000 per level |

Drive-in racks | 3,000 to 6,000 per level |

Heavy-duty pallet racks | 3,000 to 5,500 per shelf or beam |

Push-back racks | 1,650 to 2,645 per pallet position |

You can see that load capacity changes with each type. Heavy-duty frames can hold up to 44,000 pounds. This is important for big warehouses.

When you set up a pallet racking system, you must get the site ready and check the floor’s strength. Mark the layout so aisles are wide enough for forklifts. Build and anchor the upright frames tightly. Put in beams and decking, and check that everything lines up. Look at all bolts and safety parts. Teach your workers to use the racks safely. Keep up with regular checks to make sure your material handling storage system works well.

Tip: Always look at the load capacity labels on your pallet racking. Do not put too much weight on the beams or shelves. This keeps your warehouse safe and stops accidents.

Pallet racking helps you organize pallets, reach them easily, and keep your warehouse running well. Storage racks let you use tall space and store more goods. A good pallet racking system holds heavy loads, keeps pallets safe, and makes your warehouse safer.

Modern warehouses use different pallet racking types. Each type has a special design. Some racks work better for certain products. You should know the main types before you choose one. Botro Group sells many storage systems. These include selective, drive-in, cantilever, and mobile racking. You can see all their products at Botro Group Products.

Here is a table that shows the most common pallet racking types:

Pallet Racking System | Description | Inventory Method | Best Application / Advantage |

|---|---|---|---|

Selective Racking | Upright frames and beams let you reach every pallet | FIFO / LIFO | Good for many SKUs, fast-moving goods, easy access |

Drive-In / Drive-Through | Forklifts drive into storage lanes for high-density storage | LIFO / FIFO | Great for bulk storage, cold storage, small spaces |

Pallet Flow (Gravity Flow) | Pallets roll by gravity from loading to picking area | FIFO | Best for perishable goods, food, medicine, fast stock rotation |

Cantilever Racking | Uprights with arms hold long or big items | N/A | Used for lumber, pipes, furniture, odd-shaped or large items |

Most warehouses use selective racking. This system has upright frames and beams. You can move the beams to fit different pallets. You get direct access to every pallet. This makes loading and unloading easy.

Selective racking is good for warehouses with many products.

It works well for fast-moving goods. You can pick any pallet without moving others.

You need wide aisles for forklifts, so you store less than with other racks.

Selective racks are easy to set up and change. You can use them with racking or carton flow racks for more options.

Note: Selective racking is popular because it is cheap and simple. It is best when you need to reach many products quickly.

You can use selective racks in stores, food warehouses, farms, and factories. Botro Group has single-deep and double-deep options. Double-deep racks let you store two pallets deep. This saves space but makes it harder to reach each pallet.

Drive-in and drive-through racks help you use space better. Forklifts can drive into the storage lanes. You can stack pallets high and deep. This saves lots of space.

Drive-in racks have one entry and exit. You load and unload from the same side. This uses the Last-In, First-Out method.

Drive-through racks have entry points on both sides. You load from one end and unload from the other. This uses the First-In, First-Out method.

Both types are best for storing lots of the same product. You often see them in cold storage and small warehouses.

Use drive-in racks when you need to store many pallets and do not need to reach each one right away. These racks can hold up to seven times more than selective racks. Botro Group’s drive-in racks have strong frames and safe entry points.

Tip: Train forklift drivers to go slow and be careful in drive-in racks. Use the right pallet size and check for damage. Add guards to entry columns to stop accidents.

Pallet flow racks use rollers on a slope. You load pallets at the high end. Gravity moves them to the front. When you take one pallet, the next rolls forward.

This system uses the First-In, First-Out method. It is great for goods that expire or need to move fast.

Pallet flow racks save space and make restocking faster. You can store many pallets in deep rows.

These racks are common in food, drink, medicine, and cold storage warehouses.

You can use pallet flow racks for heavy loads and busy warehouses. They work well for products that need to move quickly. Botro Group’s pallet flow racks fit many pallet sizes and weights.

Cantilever racks have columns and arms that stick out. There are no front columns. This makes it easy to load and unload long or big items. The open front is good for things that do not fit on normal pallets.

You can move the arms to fit different items. The racks can be single-sided or double-sided.

Cantilever racks are best for lumber, pipes, steel bars, and furniture.

You will see these racks in lumber yards, metal shops, and furniture warehouses.

Botro Group makes strong cantilever racks from steel. You can use them inside or outside. They hold heavy loads. The arms and open design help you organize and reach long or odd items.

If you need to store long or big things, cantilever racks are strong and flexible. You can change the racks to fit your warehouse and products.

When you know about the different pallet racking types, you can pick the best one for your warehouse. Botro Group has many options, like selective, drive-in, double-deep, pallet flow, and cantilever racks. You can learn more about their storage systems on their products page.

Using pallet racking in your warehouse gives you many good things. These systems help you keep pallets neat and use space better. Here are the main benefits of pallet racks:

You can stack pallets up and across. This lets you store more in the same spot.

Pallet racking helps keep aisles open. It also helps you follow safety rules.

Workers spend less time looking for pallets. They move products faster.

You save energy. Good layouts need less light and forklifts travel shorter paths.

Pallet racks help you sort and label items. You can find things quickly.

You see what you have and restock before you run out.

Loading and unloading pallets is fast. You can get to each pallet easily.

You can add more racks or move them as your business grows.

Pallet racks hold big and heavy items. You can store lots of goods.

Fast picking and moving makes work go quicker. 11. Your warehouse looks clean and tidy with pallet racking.

Tip: Pallet racking keeps products off the floor. This helps stop damage.

There are some problems with pallet racking you should know. These systems need care to stay safe and work well. Here are some common issues:

If racks are not set up right, they can fall and break pallets.

Putting too much on racks can cause accidents and make racks weak.

Workers must learn how to stack pallets safely. This stops loads from tipping.

If you do not check racks often, you might miss damage or rust.

Broken racks can be dangerous if not fixed fast.

Bad planning can make it hard to reach pallets and lower storage space.

Not following the maker’s rules can make these problems worse.

Warehouse managers fix these issues by checking racks often. They keep loads safe and teach workers about safety. You can buy strong pallet racks and check them every day to find problems early.

First, look at what your warehouse needs. Measure the floor, ceiling, and aisles. Check for doors, windows, or anything in the way. Think about how many pallets you want to store now. Also, think about how many you might store later. If you have lots of different products, use racks that can change easily. If you need to get to pallets fast, use selective or pallet flow racks. If you store many of the same item, drive-in racks save space. Try to use space well but also make sure you can reach everything. This helps your warehouse work better.

Tip: Write down your inventory goals. This helps you pick the right system and makes picking faster.

The products you store change what racks you need. Long or big things, like lumber or pipes, need cantilever racks. Cold storage goods often use drive-in racks to save space. If you store food or things that go bad, use pallet flow racks for first-in, first-out. Look at the size, weight, and shape of your pallets. Some racks, like double-deep or push-back, need special forklifts or pallets. Always match your rack to your products. This keeps storage safe and easy.

Product Type | Recommended Rack System | Special Considerations |

|---|---|---|

Long/Bulky Items | Cantilever Racks | Open front, adjustable arms |

Perishable Goods | Pallet Flow Racks | Compatible pallets, FIFO rotation |

Cold Storage | Drive-In Racks | High-density, LIFO method |

Mixed SKUs | Selective Racking | Direct access, flexible configuration |

Safety is very important when you set up pallet racking. You must follow OSHA rules to stop racks from falling. ANSI MH16.1 gives rules for design and how much weight racks hold. RMI has tips for putting racks together and keeping them safe. Always use trained people to build racks. Never put too much on the racks. Teach workers to load and unload safely. Check racks often to find damage early. In places with earthquakes, add extra support. Fire safety is important too. Keep aisles open and use safe materials.

Botro Group has ISO9001, ISO14001, CE, BV, and SGS certifications. Their quality checks every step, from start to finish. Many people trust Botro Group for good pallet racking. One manager said, "Botro Group helped us change our storage. Their racks made picking faster and safer. We passed every safety check easily."

Note: Picking a certified supplier like Botro Group makes sure your pallet racking is safe and follows all rules.

Rack protectors help keep your pallet racking system safe. These tools protect racks from forklifts and falling things. Column protectors, corner guards, and end-of-aisle guards stop damage to upright frames. Using these protectors lowers accident risks and helps racks last longer. Safety guards and mesh panels stop products from falling. This keeps workers and inventory safe. Row spacers link upright frames. This makes racks steadier and less likely to fall.

Key rack protectors for your warehouse:

Column protectors

Corner guards

End-of-aisle guards

Safety mesh panels

Row spacers

Tip: Put rack protectors in busy spots. This helps stop damage and keeps your warehouse safe.

Picking the right decking helps you store things safely. Wire mesh decking gives a flat spot for pallets and loose items. It stops things from falling through and lets air move. Wire mesh decking also helps sprinklers work better for fire safety. Solid steel decking is strong and holds spills, but it can block sprinkler water. Perforated steel decking is strong and lets air and water pass. Steel pallet supports help wire mesh decking hold heavy loads.

Decking Type | Benefits | Best Use Case |

|---|---|---|

Wire mesh decking | Fire-resistant, supports pallets, airflow | General warehouse storage |

Solid steel decking | Strong, spill containment | Heavy or hazardous items |

Perforated steel | Strength, airflow, fire safety | Mixed storage needs |

Note: Use wire mesh decking for most pallets. It is tough, saves money, and makes things safer.

Checking and fixing racks often keeps your pallet racking system safe. Look at racks every week for damage and trash. Each month, check for missing or broken safety parts. Every three months, look for rust and make sure racks are straight and anchored. Once a year, have a pro check your racks. Always check uprights, beams, bracing, anchors, and protectors for problems. Make sure loads are not too heavy and are put in the right place. Keep racks clean and show load limits clearly. Teach your team how to load and check racks safely.

Inspection checklist:

Weekly checks for damage and trash

Monthly check of safety parts

Quarterly check for rust and straightness

Yearly pro inspection

Check load limits and placement

Write down checks and repairs

Teach staff about safety steps

Safety first: Checking racks often and fixing them helps stop accidents and keeps your warehouse working well.

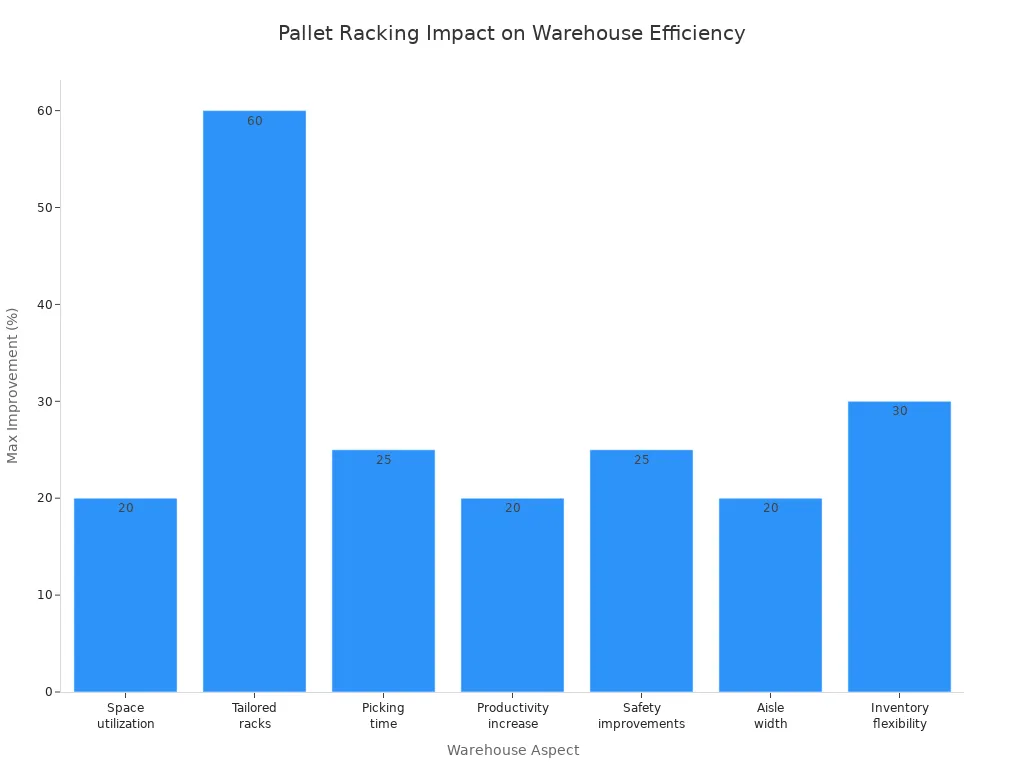

Pallet racking systems help you use warehouse space in a smarter way. They also help you finish work faster. When you pick the right system, your warehouse gets safer. You can also see workers do more in less time. The table below shows how pallet racking helps your warehouse work better:

Aspect | Impact on Warehouse Efficiency/Productivity |

|---|---|

Space utilization | Up to 20% improvement |

Picking time reduction | Up to 25% reduction |

Productivity increase | Up to 20% increase |

Safety improvements | Up to 25% fewer injuries |

Pick a system that matches what your warehouse needs. Make sure it keeps your team safe. If you want help or special answers, ask Botro Group for advice.

A pallet racking system stores goods on pallets in rows and levels. It helps you keep things neat and use space well. You can find items fast and keep the warehouse safe.

First, check your warehouse size and what you store. Think about how often you move things. Pick a system that fits your needs. Botro Group has many choices for different storage needs.

Look at racks every week to find damage. Check if any safety parts are missing. Make sure racks are straight. Teach your team to load pallets safely and follow safety rules.

People often ask about how much weight racks hold. They want to know about rack types and safety features. Many also ask how to keep racks in good shape. These are common questions for warehouses.

You can add things like rack protectors and wire mesh decking. Safety panels are also helpful. These extras keep racks safe and make storage easier. Pick what you need for your warehouse.

Introduction To Botro Mobile Roll Out Cantilever Racking System for China Project

Trackless Mobile Racking: A Game-Changer for Space Optimization in Warehouses

Exploring Mobile Pallet Racking: A Key To Streamlining Inventory Management

Trackless Vs. Track-Based Mobile Racking: Which System Is Right for Your Warehouse?