English

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-08-15 Origin: Site

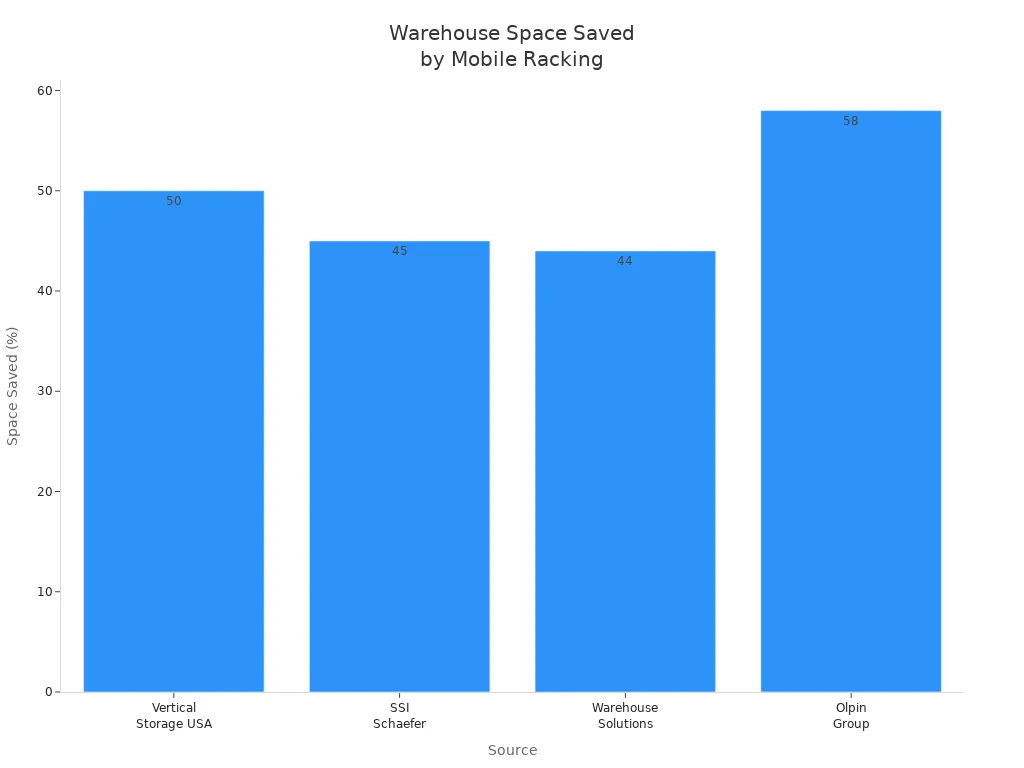

Mobile racking systems are a smart way to store things. You can move racks on rails to use more space. Unlike regular shelves, these racks move with manual or electric controls. You can slide racks together or apart. This means you do not need many fixed aisles. This design can give you up to 80% more storage space than normal racks, as you can see in the chart below.

With mobile racking systems, you can store more things in less space. This helps you use your storage area in the best way.

Mobile racking systems can save up to 80% of space. They move racks on rails and cut down on fixed aisles. These systems help people get to items by opening aisles only when needed. This makes picking items faster and more organized. Safety features like sensors, emergency stops, and barriers keep workers and goods safe. Mobile racking helps lower costs by making buildings smaller and using less energy and labor. You can see savings in about two years. Picking the right system depends on your warehouse layout and product flow. It also depends on load size and future growth plans.

Mobile racking systems help you use warehouse space better. These racks move on rails in the floor. You only open aisles when you need something. This means you do not need many fixed aisles. You can store more items in the same area.

Static racks stay in one spot. Mobile racking systems move with electric motors or manual controls. Electric motor-driven systems work well for big warehouses or heavy loads. You press a button to move racks quickly and safely. Manual systems are good for small spaces or light loads. You turn a handle or push a button to move racks. Both types save space and help you organize things.

Mobile pallet racking system options are common in warehouses. They hold pallets of goods. Heavy-duty mobile racking stores big or bulky items, the products are mainly used in manufacturing, cold storage, special material storage, etc.

Tip: Mobile racking systems can give you up to 80% more storage space than static racks.

Mobile racking systems have many important parts. Each part helps keep storage safe and easy. Here are the main components and what they do:

Mobile Frame: This base holds the racks. It moves on rails and carries your items.

Wheel Guide Rail: These rails help the mobile frames move straight.

Main Control Cabinet: You use this cabinet to control the system. It lets you set up and move racks.

Manual Control Push Button: This button lets you move racks by hand.

Electric Motor: The motor moves racks in electric systems. It helps shift heavy loads.

Safety Sensor: These sensors find obstacles or people. They stop the system to keep everyone safe.

Obstacle Detection Sensor: This sensor finds things blocking the racks. It stops movement right away.

Stop Sensor: This sensor makes racks stop at the right spot. Aisles open and close smoothly.

Station Cabinet: This small cabinet helps you check and change the system from different spots.

Bracing: Diamond-shaped supports keep the mobile bases strong.

Embedded Rails: These tracks in the floor guide the wheels.

Main Power Panel: This panel controls all mobile bases. It shows the system status.

On-board Control Panels: These panels are on each mobile base. They have movement buttons, warning lights, and emergency stops.

Remote Control: You can open aisles from far away. You can do this even while using a forklift.

Reset Button: After using an aisle, this button gets the system ready for next time.

Proximity Photocells: These sensors help racks stop safely. They keep the right space between racks.

Exterior Safety Barrier: A light curtain along the aisle cuts power if someone enters. This keeps people safe.

Interior Safety Barrier: Photocells inside the aisle stop movement if anything crosses.

Emergency Stop Buttons: These are on all control devices and at key spots. They let you stop the system fast.

Safe Load Warning Notices: These signs show storage info at the end of each rack.

Here is a table that shows the main components and their jobs:

Component | Function |

|---|---|

Mobile Frame | Moves racks and carries loads |

Wheel Guide Rail | Guides movement along the floor |

Main Control Cabinet | Central system management |

Manual Control Push Button | Allows manual rack movement |

Electric Motor | Powers rack movement in electric systems |

Safety Sensor | Detects obstacles and stops movement |

Obstacle Detection Sensor | Finds obstructions and triggers automatic stop |

Stop Sensor | Ensures accurate stopping points |

Station Cabinet | Localized monitoring and adjustments |

Bracing | Prevents deformation of mobile bases |

Embedded Rails | Provides tracks for wheels |

Main Power Panel | Controls all mobile bases and displays system status |

On-board Control Panels | Controls movement and emergency stops on each base |

Remote Control | Operates aisles from a distance |

Reset Button | Rearms the system after use |

Proximity Photocells | Ensures safe, smooth stops |

Exterior Safety Barrier | Stops system if someone enters the aisle |

Interior Safety Barrier | Stops movement if interrupted inside the aisle |

Emergency Stop Buttons | Immediate system halt |

Safe Load Warning Notices | Displays storage information |

Mobile racking systems use smart features to keep storage safe and easy. Modern systems have IoT tracking, remote controls, and AI-powered sensors. These upgrades help you check inventory in real time. They help avoid crashes and lower labor costs. Many warehouses use mobile pallet racking system setups with racks ready for automation. This is becoming more popular, especially where labor costs are high and space is tight.

Heavy-duty mobile racking is best for big, heavy items. Mobile racking works for lighter goods or documents. As online shopping grows, more companies use mobile racking systems to meet demand.

You can operate mobile racking systems in several ways. Each type changes how you store and pick items. The right choice depends on your warehouse needs and the kind of goods you handle.

Selective Racking

You get quick access to any pallet. This works best if you have many different products and need to pick items fast.

Double-Deep Racking

You store pallets two rows deep. This increases storage but makes it harder to reach some items.

Push-Back Racking

You load pallets from the front. The system uses a last-in, first-out (LIFO) method. This fits well if you want higher density and do not need to rotate stock often.

Drive-In / Drive-Thru Racking

You drive forklifts into the rack structure. This lets you store large amounts of the same product. Drive-in racks have one entry, while drive-thru racks have two.

Pallet Flow (Gravity Flow) Racking

You load pallets at one end and pick them from the other. This uses a first-in, first-out (FIFO) system. It works well for goods that expire or need quick rotation.

Mobile racking/Racking (Electrically Operated)

You move racks with electric motors. You open aisles only when needed. This saves space and makes picking easier.

Mobile racking/Racking (Mechanical Hand-Crank)

You turn a handle to move racks. This option costs less but needs more effort.

Mobile racking with Casters

You push racks on wheels. This works for small items or when you need to change layouts often.

Here is a table that shows how each type affects your workflow:

Mobile Racking System Type | Description | Impact on Warehouse Workflow |

|---|---|---|

Selective Racking | Immediate access to every pallet. | Fast picking for many products. |

Drive-In Racking | Forklifts enter to load/unload. | High storage, slower access, needs careful driving. |

Drive-Thru Racking | Forklifts pass through the rack. | Better flow, still needs safety checks. |

Cantilever Racking | Holds long or odd-shaped items. | Easy handling for special goods, less damage. |

Mobile racking (Electric) | Racks move on tracks with motors. | Saves space, quick aisle access, good for busy warehouses. |

Mobile racking (Hand-Crank) | Racks move by turning a handle. | Saves space, slower than electric, good for lighter loads. |

Mobile racking with Casters | Racks on wheels, moved by hand. | Flexible for small parts, best for small or changing storage needs. |

Note: The type of operation you choose changes how fast you can pick items, how much you can store, and how easy it is to keep track of your inventory.

You must keep your warehouse safe when using these systems. Modern designs include many safety features to protect workers and goods.

Sensors and Barriers

Sensors watch for people or objects in the aisle. If something blocks the path, the system stops moving. Light barriers and distance sensors add extra protection.

Emergency Stop Buttons

You find emergency stop buttons within easy reach. These buttons stop all movement right away. You must reset the system before starting again. This prevents accidents if someone is in danger.

Rack Guards and Panels

Guards and panels stop pallets from falling or being pushed through the rack. This keeps goods from dropping into aisles and hurting workers.

Proper Loading and Training

You must load racks the right way. Training helps workers know how to use the system safely. Good training lowers the risk of accidents.

Clear Aisles and Signage

You keep aisles clear to prevent trips and falls. Signs show where to walk and where forklifts can go.

Personal Protective Equipment (PPE)

Workers wear hard hats, gloves, and safety glasses. This gear protects them from bumps and falling items.

Regular Maintenance

You check racks and machines often. Fixing problems early keeps the system safe and working well.

Tip: Always follow safety rules and keep emergency procedures up to date. This helps everyone stay safe and keeps your warehouse running smoothly.

You want to use your warehouse space well. Mobile racking systems help you store more by removing fixed aisles. You only make aisles when you need them. This lets you fit more items in the same area. You do not have to make your building bigger. High-density mobile storage uses all the space you have. You get the best use of your warehouse. You can organize goods better. This helps you keep track of inventory. It also makes it easier to find and organize things.

Tip: Mobile racking systems help you use space well. They work great in places with little floor space.

You need to get to goods quickly. Mobile racking systems let you open aisles where you need them. This makes it easy to reach items. You can move racks close to workers. Picking is faster and takes less time. Static racks always give access, but mobile systems save space. They work for many types of products. You can change the system to fit your needs. This helps you handle different loads and stay organized. Mobile racking helps you pick items faster and make fewer mistakes.

Q: How does mobile racking affect accessibility compared to static racks?

A: Mobile racking systems make aisles when you need them. You may not reach every item right away. But you get flexible and easy access when needed. This helps you use space better and work faster.

You want to save money with your storage. Mobile racking systems use less space, so you pay less for buildings. You also spend less on energy. You can lower costs by up to 25%. Safety features help cut insurance costs. Workers do not walk as much, so they work faster. The system helps you store more and organize better. Most businesses see savings in 18 to 24 months. In cold storage, you save even more energy. Mobile racking is a smart way to save money.

Cost Factor | Static Racking | Mobile Racking System |

|---|---|---|

Real Estate Needed | 10,000 sq ft | 5,500 sq ft |

Operational Cost Reduction | N/A | 15-25% |

Picking Speed | 65 picks/hr | 85+ picks/hr |

Energy Costs | Higher | Lower |

Insurance Premiums | N/A | 5-15% reduction |

Note: Mobile racking systems help you use space better. They help you work faster and save money.

Mobile racking systems work in many places. You use them when space is small and you need to store lots of things. Here are some places where these systems help:

Warehousing and distribution centers need fast access and lots of storage. You open aisles only when needed. This saves space and makes work easier.

Cold storage facilities use space well and keep goods fresh. You lower energy costs with mobile pallet racking system setups.

Retail storage areas need small solutions for many items. You restock fast and manage things better.

Libraries and archives use mobile racking for books and papers. You store more and keep everything neat.

Museums and galleries need safe, climate-controlled storage. Mobile racking systems protect valuable items.

Automotive and aerospace industries store heavy or odd-shaped parts. Heavy-duty mobile racking gives safe and flexible storage.

Note: Mobile racking systems work anywhere you want more space and better access.

You pick a mobile pallet racking system for warehouses and cold storage. This system lets you store more pallets in the same spot. You move racks on motor bases and open aisles only when needed. This design gives up to 80% more storage. You also cut forklift trips, which lowers labor costs and makes picking faster.

Aspect | Mobile Pallet Racking System | Traditional Static Racking | Advantage |

|---|---|---|---|

Storage Capacity Increase | Up to 80-90% storage density | 50-60% storage density | Up to 80% more pallets stored in the same footprint |

Forklift Movements | 50% fewer movements | Standard number of movements | Reduced labor and operational costs |

Picking Times | 30% faster in high-volume operations | Standard picking times | Increased operational efficiency |

You save energy in cold storage because you cool less air. Lights turn on only in open aisles, saving more energy. Safety features like sensors and emergency stops keep workers safe. Botro Group offers mobile pallet racking system solutions that meet FDA rules for food and medicine. You can change aisle widths and grow as your business gets bigger. These systems help you track inventory and keep costs low.

Q: Why use a mobile pallet racking system in cold storage?

A: You get more storage, save energy, and improve safety. You can change aisle sizes and expand when needed.

Heavy-duty mobile racking helps you store big, heavy, or strange-shaped things. You put racks on strong bases that move on tracks. These systems use tough steel and hold up to 30,000 lbs per base. You get safe, smooth movement even with heavy racks.

You can change heavy-duty mobile racking with solid shelves or cradles for coils and wire spools. Cantilever racks, a kind of heavy-duty mobile racking, have no front bars. You load long things like pipes or wood easily. Botro Group gives heavy-duty mobile racking and cantilever rack choices for car and plane industries. You can change arm heights and use slanted designs for round items.

Heavy-duty mobile racking lets you use tall space and keep aisles open. You store more in less room and protect your things. You also make work safer with strong racks and easy forklift access.

Q: How does heavy-duty mobile racking help you store big or odd items?

A: You use strong racks and open designs for heavy or long things. You can change the system for different shapes and sizes, making storage safe and easy.

When you pick a mobile racking system, you want it to make your warehouse safer and work better. Look for these important things:

Strong design holds heavy or light loads and lasts a long time.

Space-saving lets you store more by having fewer aisles.

You can move racks to fit different types of items.

Higher storage density means you fit more goods in the same space.

Automated controls help racks move smoothly and quickly.

Built-in safety features like sensors and emergency stops keep people and goods safe.

The system works for cold storage, heavy items, or things that need special temperatures.

Load capacity and safety labels show the racks meet strict rules and keep your warehouse safe.

The system can change as your business grows in the future.

Tip: Always check that your system has up-to-date safety labels and gets regular checkups. This keeps everything safe and working well.

You should think about a few things before you choose. Here is a list to help you decide:

Product flow: Pick racks that match how your items move, like FIFO or LIFO.

Warehouse layout: Use all your space, including floor and height.

Pallet size: Make sure racks fit your pallets’ weight and size.

Budget: Think about the cost now and how much you save later.

Safety: Choose racks that follow safety rules and hold your loads.

Accessibility: Pick racks that work with your forklifts and are easy to reach.

Versatility: Choose racks that can change as your needs change.

Compliance Factor | Description |

|---|---|

Building Permits | Needed for tall racks; you must give special drawings. |

Seismic Compliance | Needed in earthquake areas; racks need strong anchors and braces. |

OSHA Regulations | Make sure racks are safe, labeled, and checked often. |

Load Capacity | Show weight limits checked by engineers; follow maker’s rules. |

Fire Safety | Leave space for sprinklers; use mesh shelves to help stop fires. |

Inspections | Check racks often to keep them safe and legal. |

People sometimes forget to plan for inventory, future growth, or ask experts for help. You can avoid these mistakes by planning, talking to pros, and training your team.

Customer Success Story:

A top logistics company in Southeast Asia used Botro Group’s mobile racking system. They got 70% more storage space and picked items 30% faster. The system’s flexibility and safety helped them grow their business quickly.

Ready to make your warehouse better?

Contact Botro Group for a free talk. Our experts will help you find the best mobile racking system for you.

Mobile racking systems let you use warehouse space in a smarter way. You can fit more goods and keep things safe. These systems also help your business run well, even if your needs change. Some main benefits are:

You can store more items in the same space.

It is easier to reach and organize your goods.

There are strong safety parts to protect people and items.

You save money and can change the system if needed.

Think about what you need to store now and later. It is smart to talk to experts who know your type of business. This helps you get the best results.

A mobile racking system lets racks move on rails. You only open aisles when you need to get something. This helps you use your warehouse space better. You can store more items in a smaller area.

You can fit more goods in the same space. This is because you do not need fixed aisles. Mobile racking systems help you organize your inventory better. You save space and work faster.

Yes, they are safe to use. Safety sensors and emergency stop buttons help protect people. Barriers also keep workers and goods safe. Regular checks and training make the warehouse safer.

Yes, you can use them in cold storage. You save energy because you cool less air. You can store more products in the same space. This makes your cold storage work better.

You should look at your warehouse layout and load size. Think about what you need to store and how you move goods. Safety and future growth are important too. Botro Group can help you pick the best system.

Introduction To Botro Mobile Roll Out Cantilever Racking System for China Project

Trackless Mobile Racking: A Game-Changer for Space Optimization in Warehouses

Exploring Mobile Pallet Racking: A Key To Streamlining Inventory Management

Trackless Vs. Track-Based Mobile Racking: Which System Is Right for Your Warehouse?